what rpm range does a 2.9 whipple supercharger starts to boost

Power adders come in virtually every bit many options equally Baskin-Robbins has flavors. Different types of superchargers, turbos, and nitrous all have their own unique powerbands, though none of them pack the boost response punch of a good ol' positive-deportation supercharger. Amongst those companies is a name that's synonymous with the Mustang'south heritage, and that'due south Whipple Superchargers.

"The advantage of a positive-deportation supercharger is the large amounts of torque produced at lower RPM," Dustin Whipple, of Whipple Superchargers, explained. "The positive-displacement supercharger pumps the same book of air every rotation, therefore airflow is very linear throughout the RPM range. This allows yous to get near max airflow at all engine RPM versus turbos and centrifugal superchargers, which have a very progressive airflow curve."

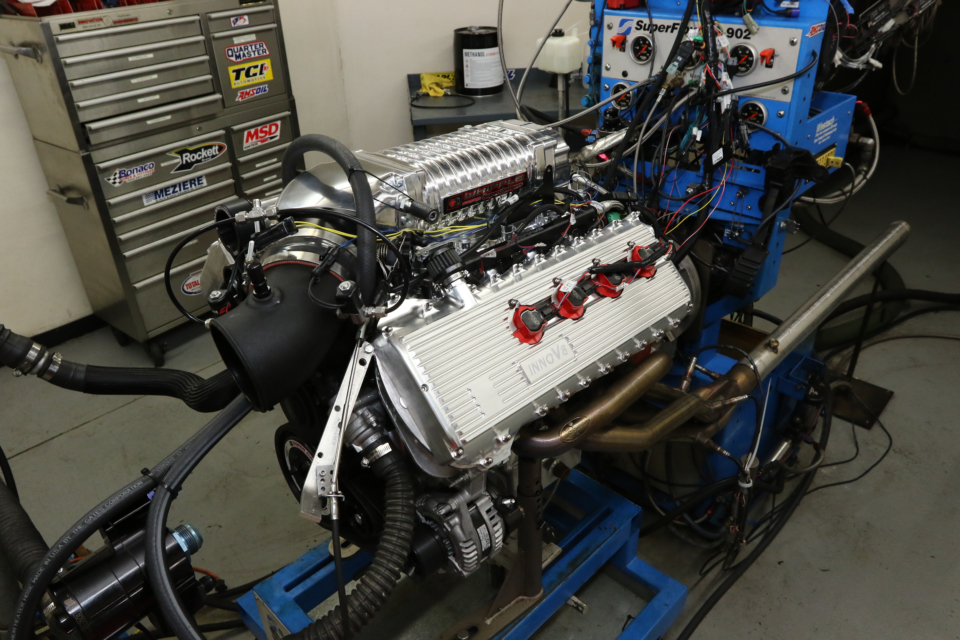

We tested Whipple's Gen ii.5 Whipple supercharger on our Coyote test mule. The two.9-liter blower was equipped with Whipple's 3-inch, 10-rib caster.

Whipple is family owned and operated visitor in Fresno, California, since 1987. It besides develops the rotors, supercharger housings, and kits in the USA. The company has over great 55 squad members and are continuing to abound with lots of new kits and products.

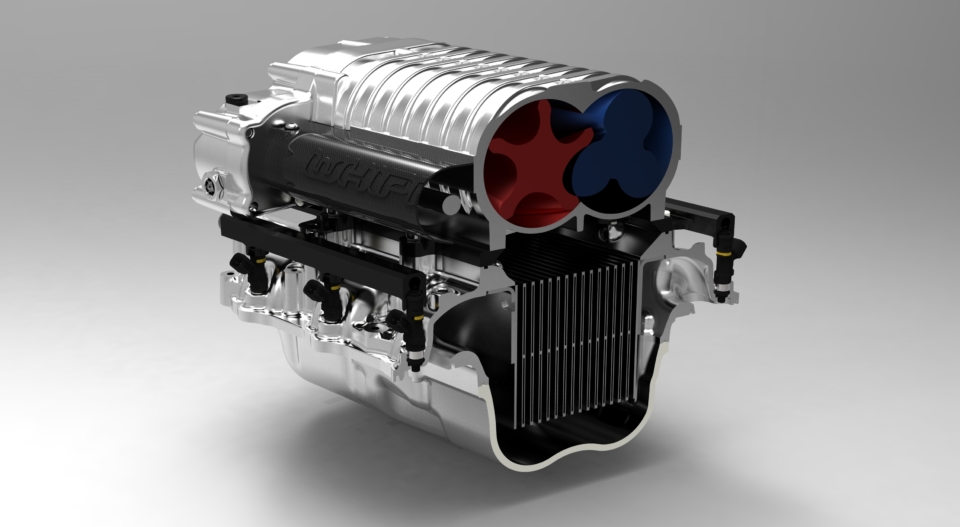

Whipple is on its third generation of the tried-and-true, twin-screw supercharger. Compact in size, this ii.ix-liter rotor group still comfortably fits nether the hood of S197 Mustangs. The front end-inlet blueprint allows Whipple engineers to hands mate a factory-style cold air inlet and subtract the number of bends required to get air into the supercharger. The rotors must be driven from the rear to let the air to enter from the forepart. This ways a jackshaft system connects betwixt the supercharger drive pulley to the rear gearbox.

A benefit of positive displacement is having positive manifold pressure with the sneeze of the accelerator. As those rotors spin together, they increase the speed and pressure every bit the air travels betwixt them.

This cutaway helps testify exactly what'southward going on inside the Whipple supercharger. Air is delivered to the rotors via the front inlet, compressed downwards, through the intercooler, then back up, and to the runners.

Volumetric efficiency and a depression reciprocating drag is the name of the game when it comes to making the almost out of your power adder. Making the compressor work as efficiently as possible increases the power per pound of boost and reduces heat. Also having a giant air-to-water intercooler cadre that fills the entire valley helps increment air density earlier the valve. The denser the air, the more of that boost you're able to pack into each cylinder.

The positive-displacement supercharger pumps the same volume of air every rotation, therefore airflow is linear throughout the RPM range. — Dustin Whipple, Whipple Superchargers

When it came to designing its intercooler packaging, Dustin explained, "Yeah, ane thing nosotros are known for is using every foursquare-inch possible. We institute, after using a competitor'south lower half in our Ford Performance package on the S197, there were limitations to the amount of cooling capacity, yet one still had to grind the block! Since we were starting from scratch, we made a core 33-per centum larger than the previous design. Nosotros opened the water passages up and changed the fin type for lower force per unit area drop. We too significantly increased the plenum area above and beneath for better airflow."

(Tiptop Left) Whipple's Gen ii.5 supercharger was a tweener between their Gen ii and 3 systems. Now fully converted to Gen 3, the 2.five included Whipple's new rotor group with the visitor's older housing and provided half of the horsepower advantage. The jackshaft arrangement allows for a front air inlet and thus simplifying the air intake plumbing. (Top Right) Our 2011-2014 Mustang kit comes complete with fully assembled hoses at the correct length. Each hose is bagged and labeled separately to avoid whatsoever confusion of their placement. (Bottom Left) Also included with the kit is a heavy-duty heat exchanger, fabricated coolant tank, and high-flow intercooler pump. (Bottom Right) New, billet fuel runway are included with their kits and we completed them with Fuel Injector Clinic's 1,650cc injectors. We ran injectors that big because we're running our engine on E85.

The Nitty Gritty

We caughtWhipple in between a transition betwixt its Gen 2 and three systems and ended upwards with their 2.v. "The Gen 2.v was a stopgap while the new housing was beingness done," Dustin said. "This featured the new rotor group with revised contour and blanket. The newer profile was a enhancement to the Gen 2. Nosotros made some large breakthroughs in rotor sealing and clearance distribution. This greatly increased functioning across the entire RPM range. The Gen three housing further enhances rotor filling and efficiency. Our next upgrade will be even one step further in performance."

Understanding The Stages

All new Whipple Stage ane-3 superchargers now feature their new Gen 3 housing and rotor group. Just at that place's no way this is l-land CARB legal right? Wrong! All complete Coyote based kits are 50-state legal.

• Phase 1: This is Whipple's base of operations supercharger system . The tune comes with a lower RPM limit, less aggressive scale and uses the stock 80mm throttle trunk. ($seven,695 retail)

• Stage 2: Even so using the stock 80mm throttle body, this stage comes with a pre-programmed fuel pump voltage booster for extra fuel supply, 1 pound of additional boost, and a more ambitious calibration. ($8,095 retail)

• Stage three: This system boasts a slightly more aggressive melody up and Whipple's elliptical 132mm barracks throttle trunk. This is good for an additional 25 horsepower and fifteen lb-ft of torque. This means the 91-octane melody upwards creates 750 creepo horsepower on only 10.five psi of heave! Whipple offers this throttle trunk in cable or drive-by-wire configuration, utilizing the factory drive motor. ($8,695 retail)

When jumping to the Phase three system Whipple includes a new front inlet that is designed for its elliptical 132mm throttle body. "A circular throttle body is better just you can't fit a massive round blade under the hood, nor parcel around it and then one is forced to squeeze it down," Dustin said. "In the past, we always had a modified oval, which had flats on bottom and elevation. They had to be massive, 170-plus mm which is incredibly hard to command and idle."

Whipple offers their barracks elliptical 132mm throttle body on their Stage three kits to deliver all the air. A drive-by-wire version of the Roval unit accepts a stock throttle torso's drive mechanism, but because we were using a Holley HP standalone, we opted for the cable-driven variant.

"In the end, nosotros came upwardly with something in between — an extremely high flowing, very near similar to a round throttle body of equal size, but far greater than a flat-blade-mode throttle body," Dustin added. "Our adept friend, Steve Turner dubbed information technology a Roval (round/oval) which stuck, so now it's the 132mm Roval, which we now have a 150mm Roval for the next power level. These tin drive similar a stock 80mm in all conditions, yet make 1,500+horsepower — the all-time of both worlds."

Regardless of what stage y'all start with the system is fully modular. Upgrade to the elliptical throttle or simply change the supercharger pulley, you can lower or increase the power which allows it to fit virtually any application.

Four More Ribs, Please!

"The ten-rib looks bully, merely works even amend," Dustin shared. "Nosotros recommend information technology after the three.0-inch six-rib combination. If you need more airflow than that, a 10-rib is the best option. Ideally, most should run the Cobra Jet style version, which pulls the alternator back and runs on the Air conditioning belt line. This shortens the length significantly which helps extend chugalug life."

(Left) When a 20-pct-overdrive ATI damper is paired up with a 3-inch supercharger pulley, the additional four ribs provided past the optional 10-rib upgrade makes a large difference. (Center) We already had a Meziere electrical water pump and we were able to easily swap out to a x-rib idler pulley. The Meziere pump comes with all the accoutrements of the stock water pump organisation for an easy installation. This pump will assistance free upward some horsepower but also allow us to wheel water through the engine while it's off. (Correct) The Whipple bracket system comes with numbered spacers to ensure belt alignment is dead-nuts. Too included in the 10-rib kit is Whipple's heavy-duty tensioner for increased belt tension.

Many supercharger kits on the market will use a stock manner, cast auto belt tensioner. To take things to the next level, Whipple decided to engineer its ain.

"About two years agone we got tired of fighting OEM-style tensioners, which are very affordable, merely impossible to control clearances and movement. Since we are tight on infinite, nosotros have to concur the chugalug in a very accurate position at all times," Dustin said. "The cast versions typically don't accept bearings to command rocking, therefore the arm's motion can sometimes push the chugalug the incorrect management. This causes many problems including noise and excessive belt wear. We made a very robust, all billet tensioner that looked cracking and was easy for the customers to install."

Our Exam Specimen

To test the upper limits of the Gen 2.v Whipple supercharger on a Coyote, we needed to start with a strong foundation. We fortified our Coyote block with Darton dry sleeves by Race Engine Development and and so had it fully assembled by MPR Engines. The brusk-block consists of a new 4340 forged Dominate 302 crankshaft, BoostLine's all-new 2,000-plus-horsepower-capable forged connecting rods, and ten:1 compression ratio JE Pistons characteristic an Electroless Nickel treatment along with DLC-coated pins. Since our engine is based on a used F-150 cadre, our compression ratio came in at 10.6:1 afterwards the heads and cake were decked.

The top end of the engine consists of COMP Cams Stage Three blower camshafts, valve springs, and retainers, Ferrea supplied the oversize valves that meld perfectly with MPR's CNC port and valve jobs. The camshafts are locked out with MPR'southward lightweight lockout plates and are supported by Livernois billet chain guides, MPR billet oil pump gears, and MPR front concatenation drive. The 20-percent-overdrive ATI Performance Products damper that's setup for a x-rib configuration properly matches up with Whipple's 10-rib upgrade for maximum chugalug traction.

Our fully built Coyote was assembled by MPR Engines. Darton sleeves, JE Pistons, BoostLine connecting rods, and all ARP hardware filled the bottom of the block. MPR's CNC ported cylinder heads, Ferrea valves, total COMP Cams valvetrain, and all the billet front bulldoze goodies rounded out our long cake.

(Left) Our engine has locked out camshafts and is running off Holley'southward HP standalone EFI organization on the dyno at Westech Operation. (Right) Fill and forget it. Whipple utilizes a self-contained oiling system and only requires the oil to be replaced every 75,000-100,000 miles. A sight drinking glass on the side helps brand fluid level checking a breeze.

Hitting the Dyno

We took our Coyote to Westech Performance for our engine-dyno testing. Due to the power levels we plan to make with our engine, our camshafts were locked out and degreed. The lobe separation angle on our Coyote was set up a little wider so nosotros didn't have to plough the motor and so high.

Nosotros decided to run the system on Holley'south HP series standalone EFI organisation. They offering a plug-and-play kit specifically for the Coyote. Rocket Make provided the E85 fuel that's pumped by Fuel Injector Clinic's ane,650cc injectors. Whipple's smallest recommended supercharger pulley is two.75-inches for the Coyote application, so nosotros decided to test our engine only above that threshold with the 3-inch caster.

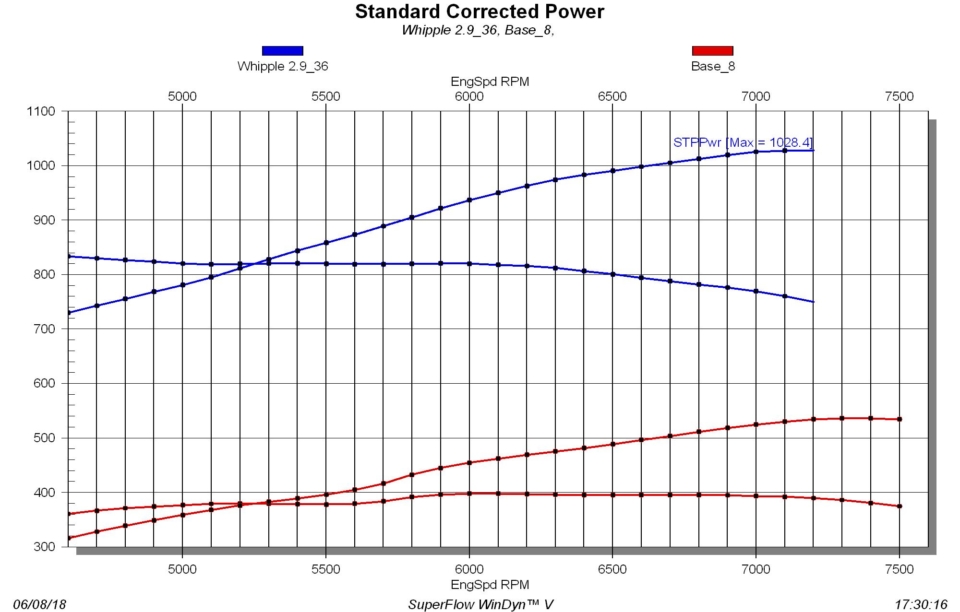

Stratospherically unlike between our earlier and after dyno runs. In one case Westech had got our air/fuel ratios where we wanted them, nosotros started to add timing and our engine was the happiest with 21 degrees of timing. While we did make 1042 hp on 1 pull, our boilerplate pull ended up at 1028.4 horsepower and 833.3 lb-ft of torque with 20 psi of boost. That'due south an overall proceeds of 492.3 horsepower and 453.6 lb-ft of torque. This ways our motor was making 24.6 horsepower per pound of boost. We only needed to spin our motor to vii,200 RPM due to our wider LSA and anything beyond that the boost slowly tapered off. Special shout out to Ken Bjonnes of Palm Beach Dyno for helping out with some tech support during our dyno session!

We were able to showcase the authorisation of Whipple'due south Gen 2.5 supercharger with its 3-inch supercharger pulley on our 2013 Coyote dyno mule. For this looking for the next level of operation from Whipple, don't fret, Whipple has more in store.

"Yes, 100 per centum, we've got quite a few upgrades coming that volition farther benefit the unabridged Coyote market place. Stay tuned," Dustin added.

Source: https://www.enginelabs.com/engine-tech/dyno-testing/making-1000hp-whipples-2-9-liter-blower-coyote/

0 Response to "what rpm range does a 2.9 whipple supercharger starts to boost"

إرسال تعليق